HERZOGENAURAUCH, Germany and DETROIT, Dec. 16, 2015 /PRNewswire/ — Innovations and technologies from Schaeffler making automobiles safer, more environmentally friendly and more comfortable will be on display at the North American International Auto Show (NAIAS) in Detroit. With its comprehensive range of products for engine, transmission and chassis applications, Schaeffler is making a decisive contribution towards “mobility for tomorrow”.

During NAIAS’s Press Preview, Schaeffler will host a press conference at 7:10 a.m. on Jan. 11 in the Ambassador Ballroom (third floor/room 360) of Cobo Center. At the press event, Schaeffler executives will discuss the global supplier’s solution to both regional and global challenges: the optimization of combustion engines-related drivetrains, hybridization and electrification; as well as it growth and development plans for North America.

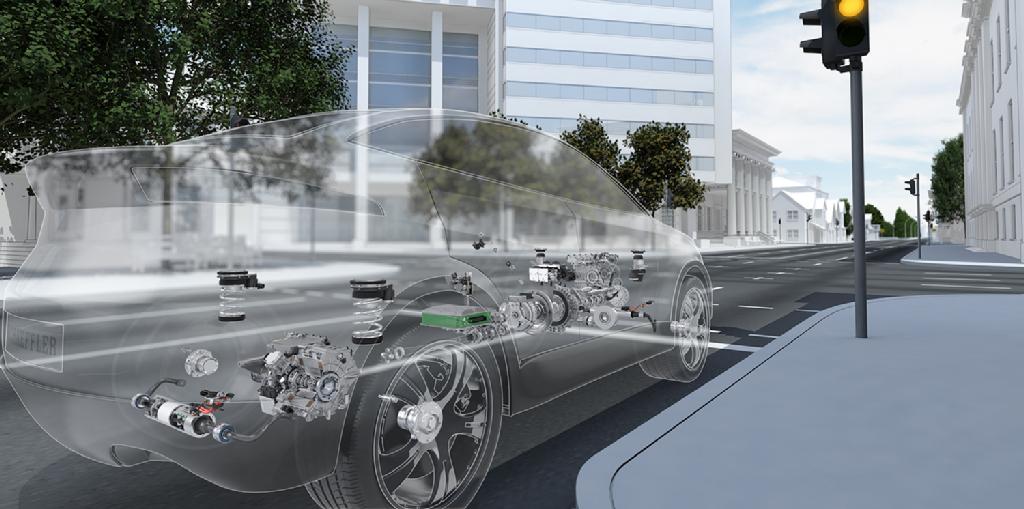

In addition to its engine, transmission and chassis products, Schaeffler’s technology exhibit will include a “glass car” containing around 40 products and technologies to provide visitors a clear insight into the company’s innovations. The model is complemented by movable screens that cover the entire length of the glass vehicle and can be used as a kind of “x-ray scanner” to learn more about the different drivetrain components.

Attractive technologies that are customized to regional requirements.

Different regions of the world have vastly different mobility requirements. However, the energy efficiency and environmental compatibility of mobility solutions worldwide is dependent on how the respective vehicle drives are designed.

“Schaeffler offers a range of products that are customized to suit the requirements and preferences of individual regions,” said Marc McGrath, president of automotive North America for Schaeffler. “The formula for our success is development work across national borders and sectors.”

On the path towards optimum overall system solutions.

The technological path that drive architectures must follow is specified by the trend for increased efficiency and the intensive electrification of the drivetrain. In this context, Schaeffler considers the internal combustion engine, the electrical components and the transmission as a whole, with particular focus being placed on the optimization of the internal combustion engine. The thermal management module (TMM) is key to reducing fuel consumption and CO2 emissions. Following its successful market launches inEurope and Asia, the TMM is now set to go into volume production on the North American market.

Schaeffler transmission technologies also play a decisive role in North America. Modern transmissions employ increasingly high numbers of speeds – with up to 10 speeds currently available – and allow the engine to be operated in the optimum area of the datamap. Damping concepts, such as the centrifugal pendulum-type absorber, allow vibrations to be reduced and speeds to be decreased as a way of optimizing fuel consumption. A new development is the combination of a torque converter with a centrifugal pendulum-type absorber.

North America is also seeing an increasing demand for drivetrain electrification solutions – an area where Schaeffler has a broad range of products and technologies. For example, Schaeffler has developed a variation on the P2 hybrid module with an integrated torque converter for the American market. This high-voltage solution represents a combination of the mobility supplier’s expertise in the fields of torque converters and hybrid technologies, and is expected to be in use in a North American light truck by 2020. The range of products on display in Detroit is rounded out by products for 48V hybridization, which provide a cost-effective solution to allow fully-electric driving at low speeds.

About Schaeffler

The Schaeffler Group is one of the world’s leading integrated automotive and industrial suppliers. The company stands for the highest quality, outstanding technology, and strong innovative ability. The Schaeffler Group makes a decisive contribution to “mobility for tomorrow” with high-precision components and systems in engine, transmission, and chassis applications as well as rolling and plain bearing solutions for a large number of industrial applications. The company generated sales of approximately 12.1 billion euros in 2014. With around 84,000 employees worldwide, Schaeffler is one of Europe’s largest technology companies in family ownership. It has a worldwide network of manufacturing locations, research and development facilities and sales companies at approximately 170 locations in 50 countries.

About Schaeffler North America

Schaeffler is a recognized development partner for global automakers and suppliers. To serve the North American automotive market, Schaeffler operates development centers in: Troy, Mich.; Fort Mill, S.C.; Wooster, Ohio; and Puebla, Mexico. The company’s 600 North American engineers and technicians, who are supported by a team of more than 6,400 global R&D engineers, drive development in the region by utilizing state-of-the-art test and measurement equipment, computational tools and CAD systems. Schaeffler Automotive has headquarters in Fort Mill and manufacturing facilities in: South Carolina; Missouri; Ohio; Ontario, Canada;Puebla and Irapuato, Mexico. For more information.

[“source-prnewswire”]